Tunnel personnel location system

Introduction of Positioning System

Brief Introduction of Technological Advancement

UWBLOC positioning system uses a technology based on UWB carrier-free communication principle to achieve positioning. UWBLOC technology uses nanosecond to microsecond non-sinusoidal narrow pulse to transmit data. By transmitting very low power signals over a wide spectrum, UWBLOC can achieve data transmission rates ranging from hundreds of Mbit/s to several Gbit/s in a range of about 300 meters.

UWBLOC technology has strong anti-jamming performance, high transmission rate, large system capacity and very small transmission power. UWBLOC system transmits very small power, communication equipment can be used less than 1 mW transmission power to achieve communication. Low transmitting power greatly prolongs the working time of power supply. Moreover, the effect of electromagnetic radiation on human body will be very small if the transmitting power is small

The Location System can achieve the highest positioning accuracy of 10 cm, millisecond delay real-time display of personnel position.

UWBLOC signals almost do not interfere with wireless devices operating at the same frequency. UWBLOC signals have very strong penetration ability and can be positioned accurately in indoor and underground space, such as tunnels and pipelines, while GPS positioning system can only work within the visual range of GPS positioning satellites. Unlike GPS providing absolute geographical position, UWBLOC pulse positioner can give relative position. In addition, UWBLOC wireless locator is cheaper.

Positioning principle

As shown in the following figure, the UWBLOC base station needs to be installed on the tunnel wall. The staff wears the UWBLOC tag. The tag is an active beacon. The tag sends a signal pulse in every second. The base station receives the signal pulse. The distance between the tag and the base station can be calculated by the time when the pulse reaches the base station. At last, the real-time position of the staff can be obtained through complex signal processing.

It should be noted that the antenna of the signal base station should be far away from the metal occlusion object, because the metal object will reflect the pulse signal, which will lead to the signal loss when the base station can not receive the signal pulse from the label, thus leading to the failure of location.

When installing a base station, it is necessary to determine the distance between each base station and the entrance, so as to calculate the distance between the personnel and the entrance accurately.

System Topology Diagram

Cable transmission mode is a communication scheme designed for long distance tunnel. Base stations are connected by transceivers. Transceivers transmit data to the server of the tunnel monitoring center through optical fibers. The location coordinates of each location beacon are obtained by real-time operation of the personnel location engine software installed on the server. Managers can view the real-time position of the personnel through the display, and can also transfer the data of all base stations to the positioning engine server of the monitoring center. The information such as the name of the staff member, duty, the time of entry and exit of the tunnel are displayed on the LED display screen at the tunnel entrance.

UWBLOC pulse wireless communication is used between beacon and base station. The staff can wear the beacon on their hands or fix it on the safety helmet.

Basic function introduction

1. Locate the location information of each person accurately and display the information on the electronic map of the monitoring center.

2. Automatic attendance statistics function can automatically record the names ,position and the time of entering and display these information on the large LED screen in the monitoring center.

3. Track playback function, the system supports querying the movement track of any person in a certain period of time, and can look back at the last stop position of each person in the event of a safety accident.

Power supply for the base station

UWBLOC base station support standard POE power supply.

POE power supply is shown in the picture below:

Power supply for the location label

As shown in the picture below, the positioning label is powered by lithium batteries. If the lithium batteries are running down, the label will flash the red light to remind you that the lable need to be charged, and it can be charged by the USB data line. Usually it can be fully charged within 2 hours and the green light will be on when it is fully charged.

Installation for the base station

The installation height of the positioning base station should be as high as possible, and away from occlusion, and the distance between the two base stations should not be greater than 300 meters (100 meter for this project). This is to ensure that the location label can communicate with at least two base stations at the same time in order to locate.

Base station antennas need to be installed vertically and downwards.

During installation, the coordinates of each base station should be determined, and the tunnel portal should be used as the origin.

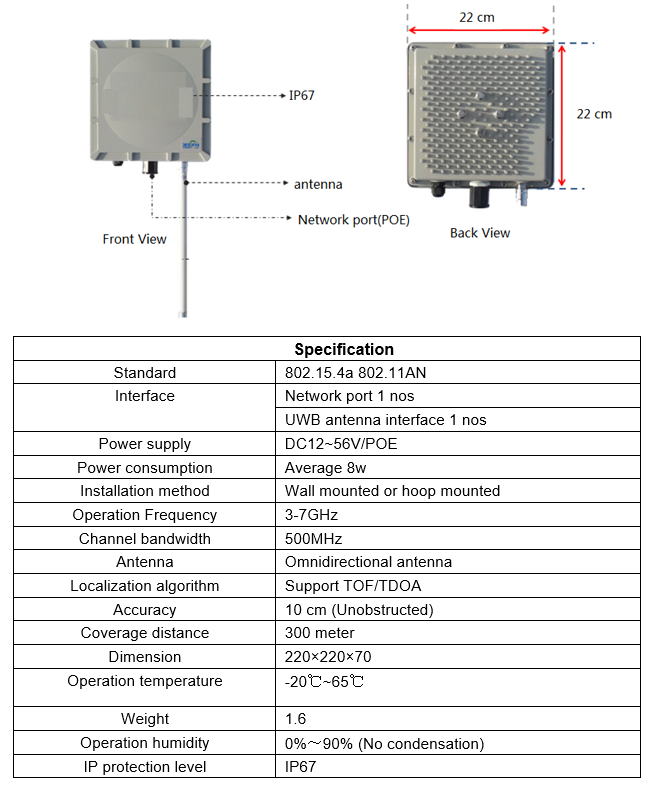

Base station specification

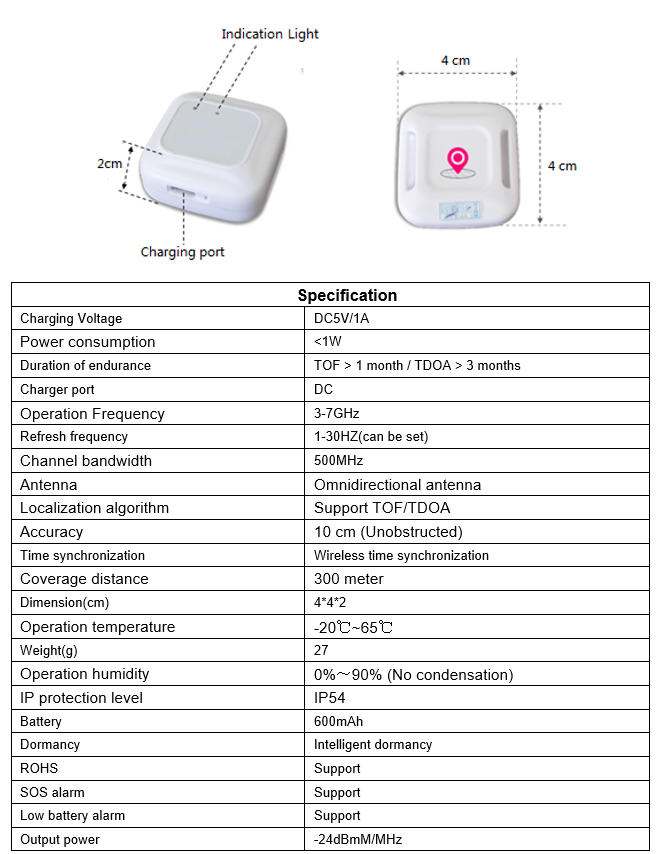

Location label specification

-

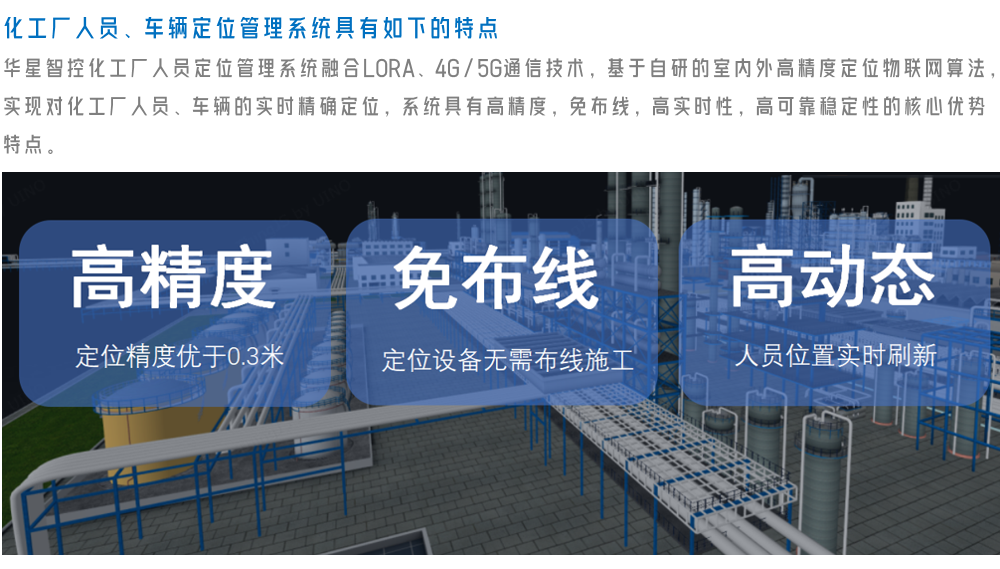

化工、石化、炼油厂人员及车辆定位方案

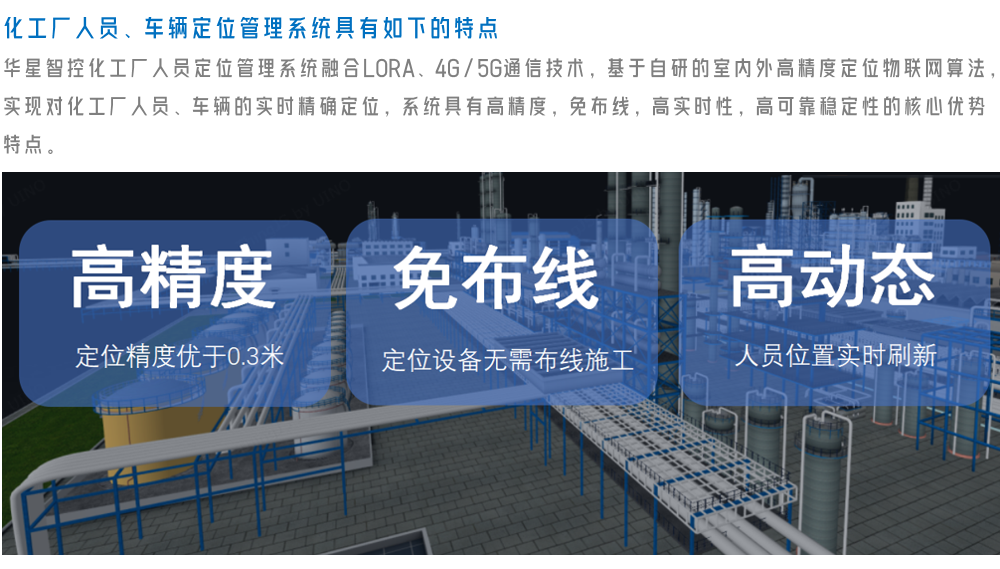

化工厂人员、车辆定位管理系统具有如下的特点:华星智控化工厂人员定位管理系统融合LORA、4G/5G通信技术,基于自研的室内外高精度定位物联网算法,实现对化工厂人员、车辆的实时精确定位,系统具有高精度,免布线,高实时性,高可靠稳定性的核心优势特点。

-

行车、天车防碰撞方案

通过在行车上安装精准测距基站,基站之间实时互相测距,设定一个危险距离R,当行车2和行车1或者行车3的距离小于R时,就会触发继电器工作启动声光报警器提醒司机或者切断电源让天车停止工作。

-

矿山人员车辆定位管理解决方案

矿山人员车辆定位方案是一种设计用于跟踪矿区内运载矿山人员的车辆位置的系统。 该系统通过提供车辆的实时位置信息,对于确保人员安全至关重要。 以下是矿山人员车辆定位方案的一些关键组成部分:GPS跟踪:该方案利用GPS(全球定位系统)跟踪矿山人员车辆的位置。 GPS 跟踪提供准确的位置数据,可用于监控车辆的速度和方向。车辆跟踪软件:从车辆收集的 GPS 数据被发送到中央系统,该系统使用车辆跟踪软件在地图上显示车辆的实时位置。通讯设备:该方案还需要无线电或手机等通讯设备,让车上人员能够与控制室和应急服务部门进行通讯。地理围栏:地理围栏是一项允许该方案在矿区内设置虚拟边界的功能。 如果车辆进入或离开地理围栏区域,该方案将向控制室发出警报。应急响应:该方案应制定应急响应协议,以防发生事故。 这可能涉及应急小组、疏散计划和急救设备。总体而言,矿山人员车辆定位方案是矿山安全的重要组成部分。 通过提供实时位置数据,该方案可以帮助预防事故并对紧急情况做出快速反应。

-

叉车防碰撞方案

车与人防碰撞:叉车上安装精准测距模块和声光报警器,预先设定好安全距离R,测距模块与人员携带的标签测距L,当距离小于预先设定的安全距离R时就触发测距模块的继电器接通声光报警器工作提醒驾驶员注意。

-

工业智能制造,电力电厂,钢铁治金定位方案

高精度人员、物资、车辆精准定位系统基于多维技术融合方案,可以实现10~30厘米的精准位置数据采集,可用于工业智能智能制,造汽车装配,电力电厂,钢铁治金等行业实现对工厂内的人、车、物、料等的精确定位、无缝追踪、智能调配与高效协同,大幅提升工厂的精益生产及精细化管理水平。

-

数据机房人员定位方案

通过在机房内布设有限数量微基站,实时精确地定位巡检人员上的微标签位置,零延时地将巡检人员位置信息显示在机房控制中心,进行安全区域管控、人员在岗监控等。精度达到10厘米级,精确管控以优化流程、合理调度安排、提高数据机房的巡检效率。

-

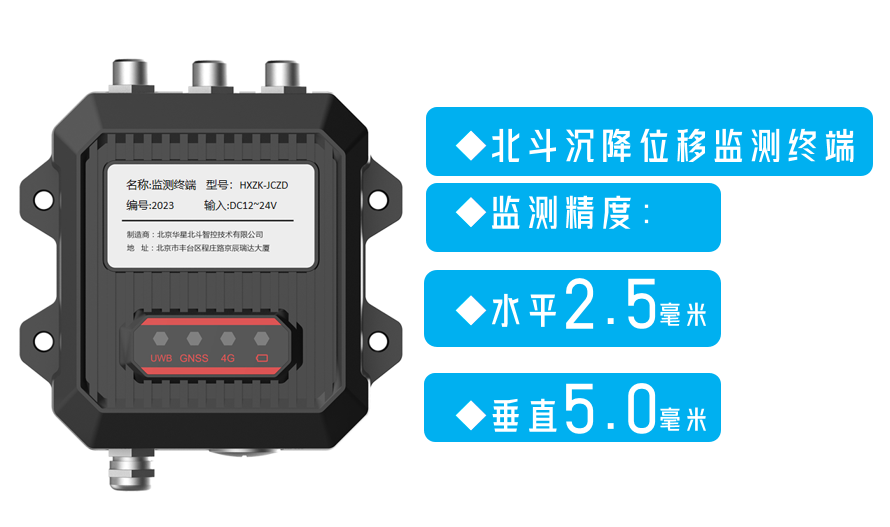

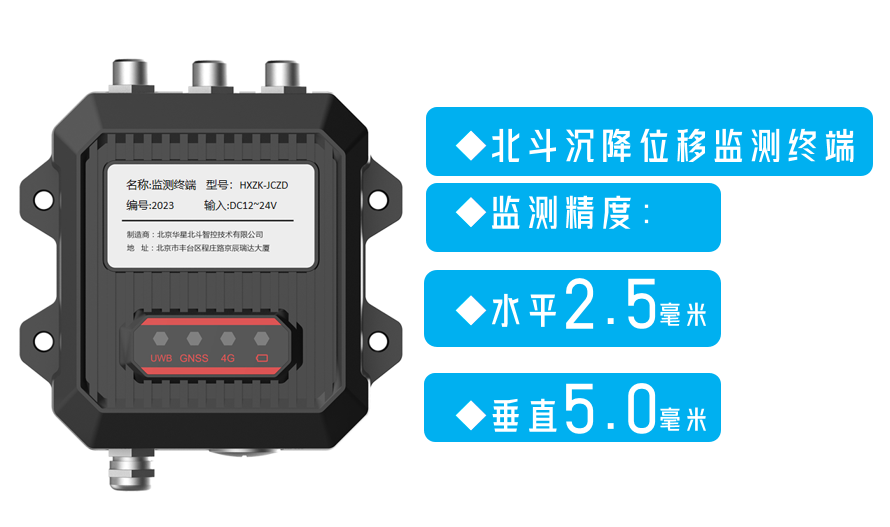

北斗储油罐、滑坡、采空区位移变形监测方案

北斗位移监测可实现水平±2.5毫米,垂直±5.0毫米的位置变化监测,可以用于滑坡,道路边坡,采空区,尾矿库,水库大坝,铁塔,储油罐等的形变监测,通过长期的连续监测,掌握被监测体的位置变化趋势,避免灾害事故发生。

-

隧道错车智慧调度方案

铁路隧道施工过程中,由于隧道宽度比较窄,只在固定的距离处有错车位置,当车辆交汇位置距离错车位置比较远的时候车辆需要倒车到错车位置才能错车,这就会导致花费很多时间来错车,大大的降低了工作效率。